+91 7042496725, +91 7042496726 |

+91 7042496725, +91 7042496726 |  service@durst-india.com

service@durst-india.com

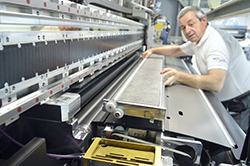

Industrial multi-function printing system for textile production

With the Rhotex 180 TR, Durst has expanded its textile direct printing portfolio with dye sublimation technology. Printing on sublimation paper and the transfer process using a calender minimizes production expenditure and enables those not in the industry to enter the field of textile production.

The printing system is especially suitable for polyester and polyester blends used in clothing, interior textiles and soft signage, for example.

Durst now offers an optional "Direct-printing kit" for the Rhotex 180 TR. Direct printing is relevant not only for flag materials, but also for standard materials where the intermediate step with paper can be dispensed with. With this expansion, the Rhotex 180 TR has been promoted to a multi-function printing system with an industrial production speed of 200 sqm per hour and a maximum printing width of 1850 mm. Direct printing and transfer printing use dye-sublimation inks, which are water-based, odorless, skin-friendly and free of volatile organic compounds (VOCs). The drying process and temperature can be set using the operating software of the printing system based on the printing type and material used. Printed textiles do not require post-treatment.

Conversion between transfer and direct printing takes only a few minutes and can be handled by a single operator.